Deciphering the Differences: XLPE vs. EVA Foam

In the realm of foam materials, confusion often arises between XLPE (Cross-Linked Polyethylene) and EVA (Ethylene Vinyl Acetate), particularly in North America where the terms are sometimes used interchangeably. Yet, understanding the nuances between these two materials is crucial for selecting the right one for your specific needs. In this article, we aim to demystify XLPE and EVA, offering practical insights into their characteristics and applications.

Let's start with the basics: XLPE stands for Cross-Linked Polyethylene, while EVA stands for Ethylene Vinyl Acetate.

XLPE Polyethylene Foam vs. EVA:

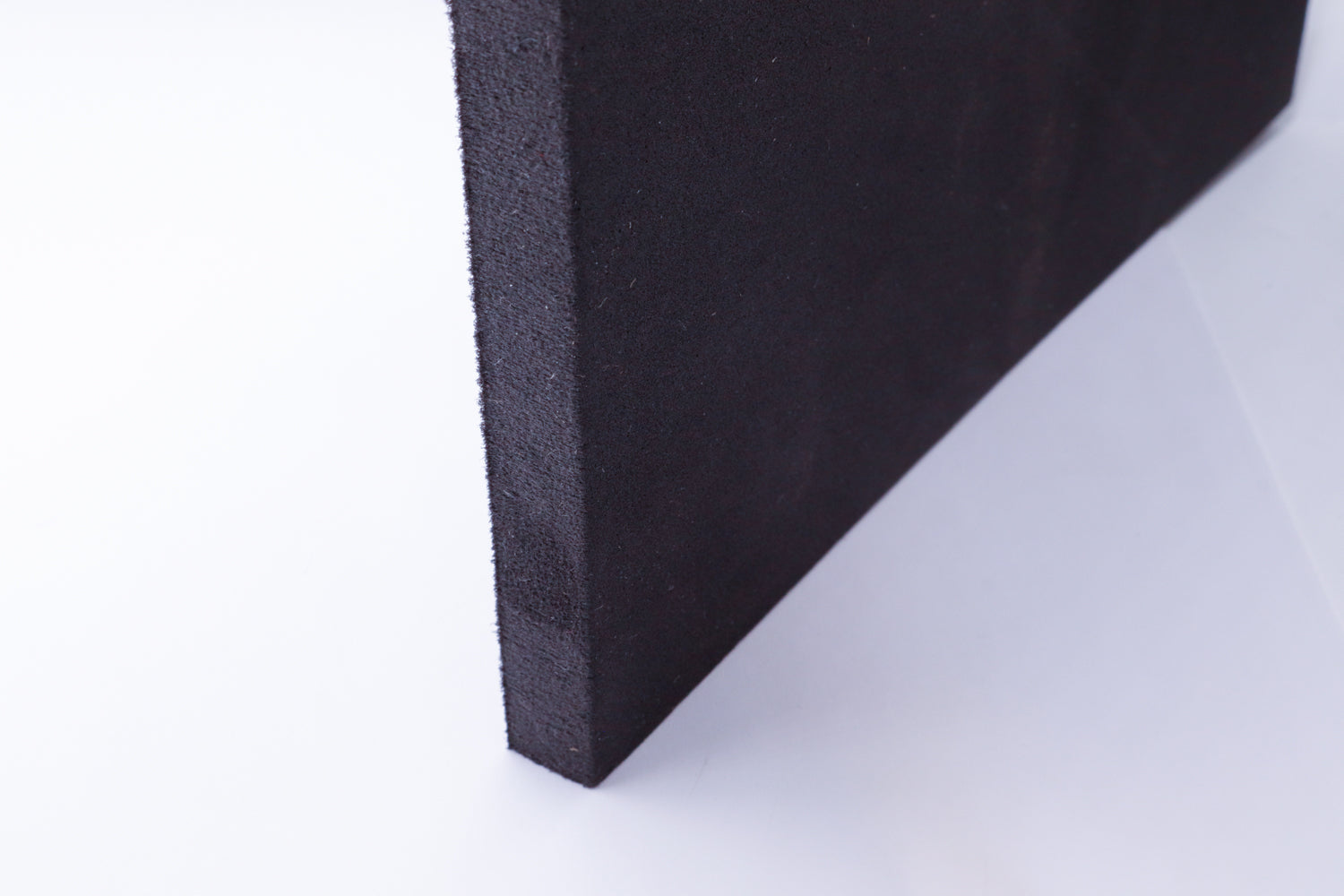

In the production of XLPE foam, a chemical agent is introduced to cross-link the polyethylene molecules, resulting in a robust three-dimensional cellular structure. This process yields a foam with fine cell structure, smooth surface, excellent shock absorption, and resistance to chemicals. Thanks to its closed-cell nature, XLPE does not absorb moisture, oil, or other substances.

On the other hand, EVA foam undergoes a similar manufacturing process to XLPE, as both materials are polyolefin-based. However, EVA foam is an ethylene copolymer with a higher percentage of vinyl acetate (VA) additive. This addition enhances the foam's softness and elasticity.

In simple terms, when comparing foams of the same density, EVA feels softer and more "cushioned" compared to XLPE. However, this distinction doesn't inherently make EVA superior to XLPE, nor does it directly impact shock absorption capabilities. The suitability of each material depends on the specific requirements of the application.

Practical Applications:

XLPE foam finds extensive use in automotive returnable packaging, case inserts, tool controls, shelving, racking, and various protective packaging applications where shock absorption and surface protection are paramount. Its durability and resistance make it an excellent choice for demanding environments.

Conversely, EVA foam is commonly employed as padding in sports equipment, such as helmets and knee pads, and is a popular material for crafting shoe insoles. Its softer texture and elasticity provide comfort and support in dynamic activities.

In conclusion, while XLPE and EVA foams share some similarities in their manufacturing processes, their distinct properties make them suitable for different applications. Understanding these differences empowers consumers to make informed decisions when selecting the appropriate foam material for their projects. Whether it's the robust resilience of XLPE or the cushioned comfort of EVA, each material serves a unique purpose in various industries and endeavors.

Leave a comment